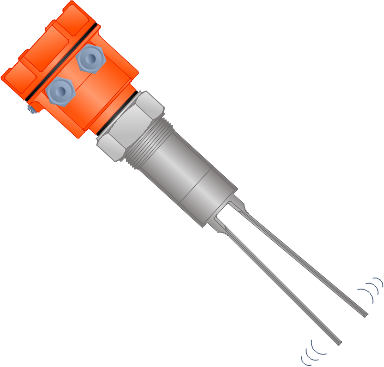

About LSV

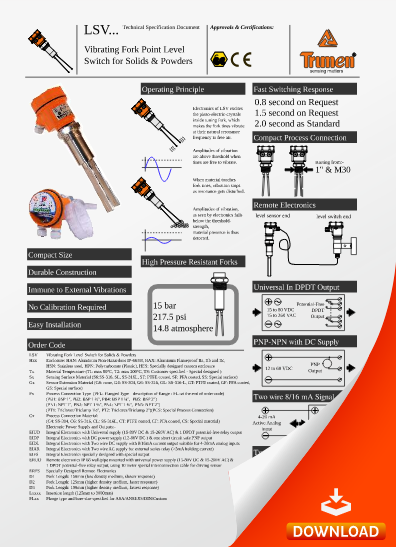

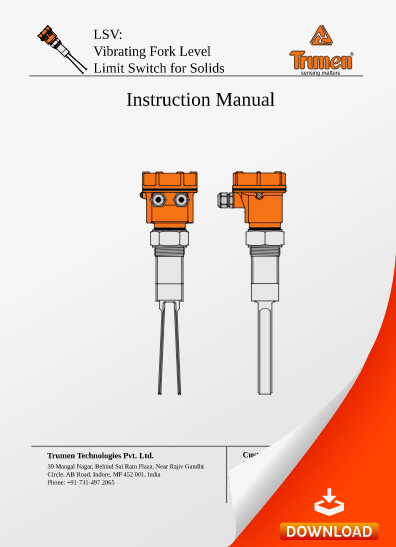

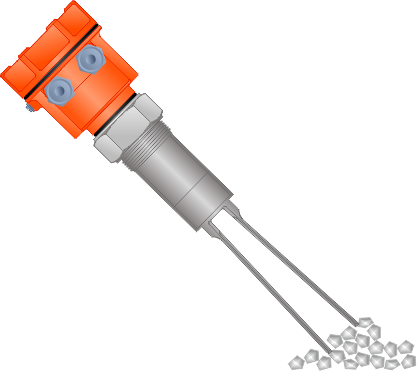

Trumen vibrating fork point level switch, model LSV suitable for solids, granuals and powder even with a low bulk density materials. Trumen model LSV is available in three different fork length depending upon the material bulk density Model LSV is available in three different tine length i.e. D1 (150mmm), D2 (125mm) and D3 (100mm). All these three different length of tuning fork have different operating frequency depending upon their length.

Know MoreAbout Trumen

Trumen came into existence in 2009 and initially started with manufacturing of Tuning Fork Level Switches for liquid and solid applications. With time, the manufacturing range increased with addition of Capacitance Level Transmitter & Capacitance Level Switches, RF Admittance Level Switches, Rotating Paddle Level Switches, Conductivity Type Level Switches, Vibrating Rod Level Switches, Hydrostatic Level Transmitter, Radar.

Know More

Features

- Compact in size.

- Calibration-less Operation.

- Universal power supply on same terminals.(15 to 80VDC or 15 to 260VAC)

- Inbuilt settable switching delay 5 sec.

- Tropicalized sealed electronics module and easy maintenance.

- Customized process connectionthreaded/flanged/hygienic etc.

- Various output options available (DPDT, PNP, 8/16mA).

Application

Trumen Vibrating Fork Level Switch is used in differentapplications like --

- Free flowing powders, fly ash, cement, PVC powder,wheat grains, pulses, polyester chips etc. Andmaterial having granuals size less than 10mm.

- Process temperature maximum 200° C/ 250° C(available on requirement)

- Operating pressure 20 bar maximum.

PVC Powder

Wheat grain

Pulses

Polyester chips

Operating Principle

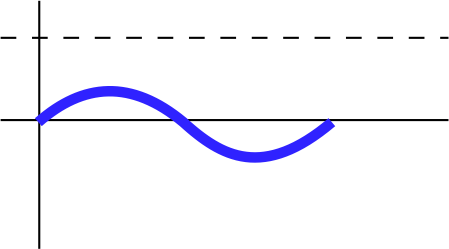

Electronics of LSV excites the piezo-electric-crystals inside the tuning fork, which makes the fork tines vibrate at their natural resonance frequency in free air.

Amplitudes of vibration are above threshold when tines are free to vibrate.

When material touches the fork tines, vibration stops as resonance gets disturbed.

Amplitudes of vibration, as sensed by electronics falls below the threshold strength, material presence is thus detected.

Operation

Device operation and settings:Trumen vibrating fork level switch is very easy to operate-

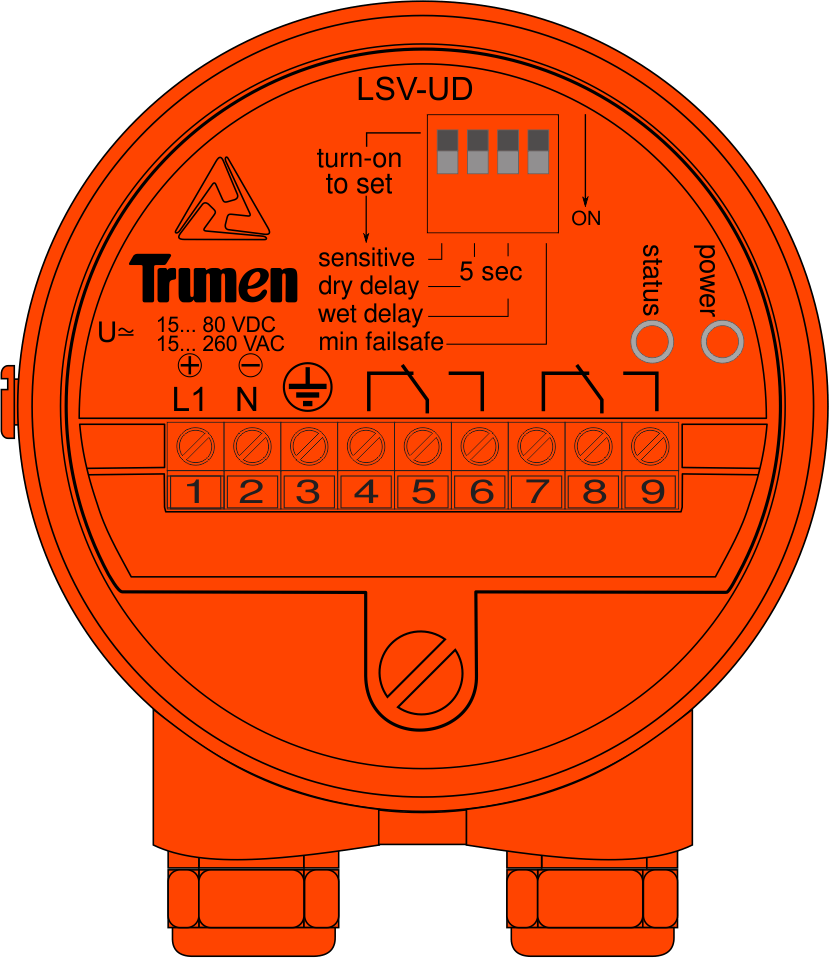

- Open the cover of Trumen LSV you can see there are 9 terminals. Terminal 1, 2 & 3 are for auxiliary power supply. Terminal 4, 5, 6 & 7,8,9 are for relay output. There are 4 DIP Switches provided on connection panel Via DIP switch 1 we can set the sensitivity that means if the material is fluffy in nature or having low bulk density (less than 200gm/litre) we need to ON switch no. 1 in this condition LSV will sense the material. Keep it turned-off for normal density (more than 200gm/litre) materials. Switch no. 2 is to set dry delay means off delay, sensor will wait for 5 sec. Once the material goes below the sensor. Switch no. 3 is to set wet delay means on delay, sensor will wait for 5sec. Once the material touches the sensor. Switch no. 4 is to set failsafe means the instruments should be in alarm condition if the sensor facess power failure. Means if we are using sensor for high level we should keep this switch OFF. And if we are using sensor for low level we should keep this switch ON.

Connection Terminals

- + of DC or Live of AC Supply input

- - of DC or Neutral of AC Supply input Supply:15 to 80VDC or 15 to 260VAC 50/60Hz

- Earth terminal for safety

- Normally connected terminal of contact 1

- Common terminal of contact 1

- Normally open terminal of contact 1

- Normally connected terminal of contact 2

- Common terminal of contact 2

- Normally open terminal of contact 2

- Connect the power supply either 15 to 80VDC or 15 to 260VAC on terminal 1 & 2

- Trumen vibrating fork level sensor (LSV) starts vibrating in air. Power LED is on and status LED is in OFF condition.

- Now we fill the material solids, granuals or powder up-to the fork tines level.

- You can see the status LED of LSV is on means material reaches to the high level.

- Relay status also change from NC to NO.

- You can set the sensitivity through DIP switch No.1.

- Dry delay is set via DIP switch No.2. On the DIP switch No.2 and empty the material you can see LSV wait for 5 sec and after 5 sec it generate switching.

- Wet delay is set via DIP switch No.3. ON the DIP switch No.3 and fill the material you can see LSV wait for 5 sec and after 5 sec it generate switching.

- Fail safe can be set via DIP switch No.4. When the sensor is installed for high level keep the DIP switch no. 4 in turn-off failsafe high or maximum & when the sensor is installed for low level keep the DIP switch no. 4 in turn-on failsafe low or minimum.

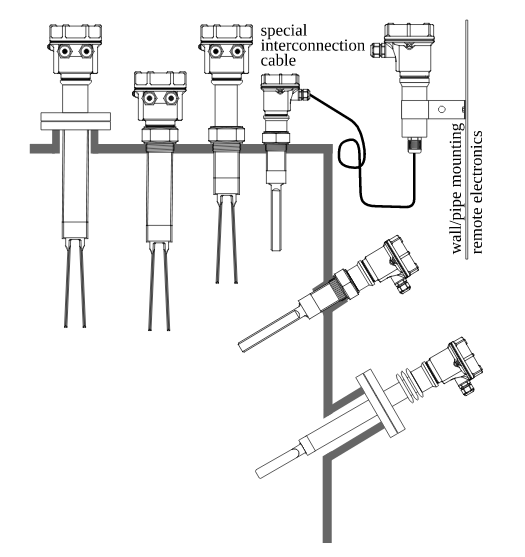

- You can easily replace the electronics as shown.

Typical Mounting

Product Video

Testimonials

Trumen Export To

UK

UAE

Turkey

Tanzania

Poland

Malaysia

Lithuania

Macedonia

Iran

Italy

Denmark

Chile

France

Japan

Argentina

Kuwait

Canada

Sri Lanka

Korea

Thailand

USA